Growing interest in sourcing equipment through brush cutter wholesale in China and selecting a brush cutter for sale high quality model often brings buyers to a practical challenge: how to read and compare specifications in a way that truly reflects real-world performance. Instead of relying on broad descriptions, project managers and field operators usually benefit from examining technical details that influence handling, durability, and long-term operating cost. Understanding how each specification affects day-to-day work helps buyers choose machines suited to their terrain, workload, and maintenance capacity.

Engine Displacement and Power Characteristics

Larger displacement engines generally provide stronger cutting capability, yet this does not automatically mean they suit every scenario. Buyers should consider the density of vegetation, the typical duration of each operation, and the level of control operators require.

For lighter vegetation or shorter tasks, mid-range displacement often provides a more manageable balance between fuel use and handling. For dense brush or extended shifts, a higher displacement engine may support smoother cutting with less strain on the engine. Instead of focusing on peak values, buyers should focus on whether the engine power curve aligns with their type of work, such as frequent starts, prolonged trimming, or tackling thick stems.

Two-stroke and four-stroke engines also differ in sound level, fuel mix requirements, maintenance pattern, and weight. Understanding these differences helps buyers match engine type to their environmental conditions and internal maintenance resources.

Weight Distribution and Operator Comfort

A brush cutter specification list often includes overall weight, but the distribution of that weight can be just as influential. When comparing models sourced through wholesale channels, buyers should examine how the weight is balanced between the powerhead, shaft, and cutting assembly.

Even a brush cutter for sale high quality can feel tiring if the weight rests too heavily on a single point. Balanced machines reduce operator strain during sweeping motions and prolonged use. Shoulder straps, handlebar style, and vibration control systems also affect fatigue levels. For teams working across large areas, ergonomic features may prevent the need for extra breaks and support steady workflow throughout the day.

Users with different heights and strength levels may prefer different handle designs, so checking the adjustability of grips, shaft length, and harness fit is essential when evaluating specifications.

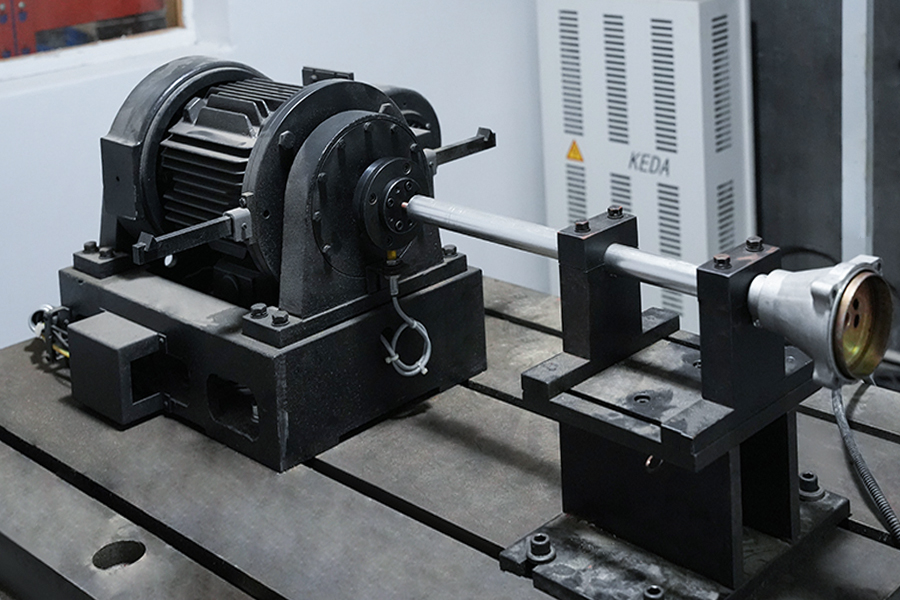

Shaft Structure and Durability Considerations

Straight shafts and curved shafts behave differently in fieldwork. Straight shafts generally offer stronger torque transfer and better performance in dense vegetation. Curved shafts are more suitable for lighter trimming and maneuvering around obstacles.

Buyers evaluating brush cutter wholesale in China should confirm the material and thickness of the shaft tube, as these influence durability during long-term use. Internally, the quality of the drive cable or solid steel drive shaft affects vibration, noise level, and resistance to torque load.

The connection points between the shaft and gearbox should be inspected for reinforcement. Clear information from suppliers on gear ratio, housing material, and lubrication method helps buyers estimate how the gearbox will perform under frequent usage.

Cutting Head Configuration and Compatibility

The cutting head determines how efficiently the machine handles different vegetation types. String heads work well for grass and softer stems, while metal blades or multi-tooth blades are suited for heavier brush. Buyers should evaluate whether the machine supports interchangeable cutting heads, especially for projects where vegetation type varies by area or season.

Compatibility with local blade types, trimmer lines, and replacement parts is another factor. A brush cutter for sale high quality often supports several blade options, but confirming thread size, guard dimensions, and attachment method helps avoid compatibility issues later.

Some buyers overlook the role of the debris guard. Its size and shape influence both safety and operator visibility. Specifications should indicate guard material, coverage angle, and mounting style.

Fuel Tank Design and Consumption Pattern

While fuel capacity is easy to compare, buyers should also consider how tank shape and placement affect balance and heat exposure. Tanks positioned too close to the engine may warm rapidly, while poorly shaped tanks may restrict fuel flow when tilted at certain angles.

Consumption rate matters for budgeting and planning field operations. A unit with moderate fuel consumption can support longer working intervals without frequent refueling, which is helpful during large-scale clearing projects. R

English

English русский

русский Español

Español عربى

عربى