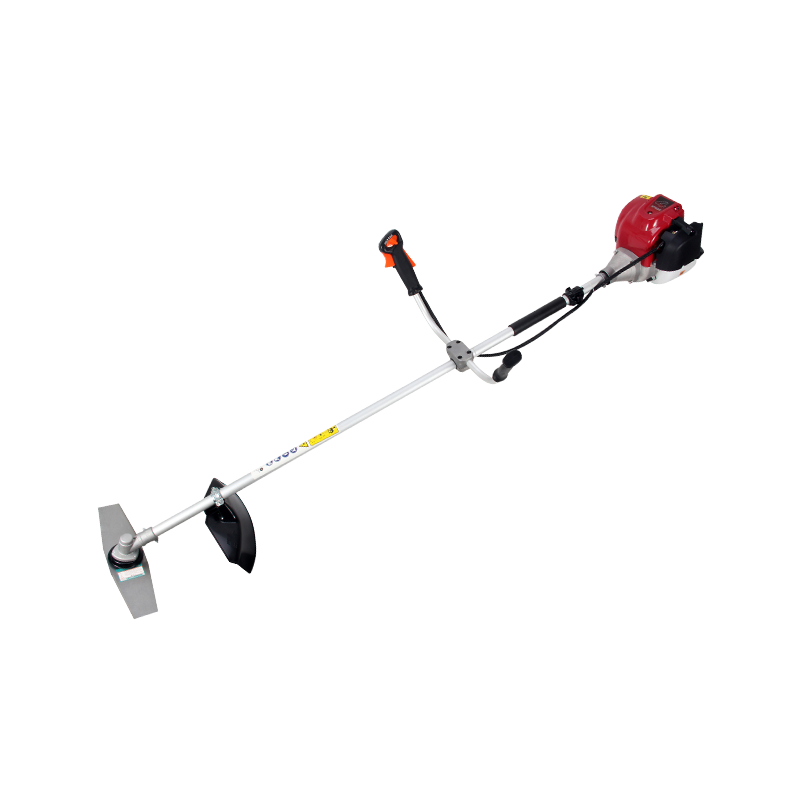

When buyers search for a brush cutter for sale high quality, they often compare engine power, cutting ability, and design comfort. Yet another factor that directly influences long-term use is the availability and function of gear case shaft spare parts. For the BG35H Knapsack Grass Trimmer Head Petrol Brush Cutter, these components play an important role in sustaining cutting performance and ensuring users can maintain their equipment with confidence.

Power Delivery Through the Gear Case

The BG35H is equipped with a 35.8cc petrol engine that generates strong power for trimming grass, brush, and even small saplings. However, the efficiency of this power depends heavily on how the gear case transfers torque to the cutting head. The gear case is designed to manage high rotational speeds while protecting internal parts from dust, moisture, and impact. When this part is durable and properly maintained, the brush cutter delivers smoother performance, reduces unnecessary vibration, and ensures steady operation during demanding work.

Knapsack Design and Stress on Internal Parts

The BG35H’s knapsack design reduces strain on the arms and shoulders by distributing weight across the user’s back. While this feature improves comfort, it also means the machine may be used for longer periods compared to traditional handheld models. Extended use places greater demands on the gear case and shaft. This makes access to replacement parts especially valuable, as it allows users to keep the machine in working condition even after hours of continuous operation in fields, gardens, or construction sites.

User Experience and Cutting Consistency

Cutting through thick grass and brush requires consistent blade speed. The gear case and shaft ensure that the power generated by the engine translates into stable rotation at the cutting head. If either of these components wears out, the user may experience uneven cutting or more frequent interruptions. By replacing worn parts with appropriate spares, operators maintain efficiency and avoid the frustration of having to push harder to achieve the same results. This contributes to both a smoother workflow and a more comfortable user experience.

Maintenance Practices for Longevity

Regular inspection of the gear case and shaft helps prevent costly breakdowns. Signs such as unusual noise, heat, or vibration can indicate wear that should be addressed quickly. Lubricating the gear case, cleaning debris from around the cutting head, and ensuring the shaft is securely aligned are simple steps that extend the life of the BG35H. With spare parts available, maintenance becomes less of a burden and more of a practical way to keep the tool working effectively over time.

Application Environments That Test Durability

The BG35H is designed to handle diverse tasks in landscaping, agriculture, forestry, and public park maintenance. Each of these environments places stress on the gear case and shaft in different ways—dense vegetation in forestry, frequent trimming in agriculture, or long operation times in large recreational areas. The ability to replace worn parts directly supports these demanding applications, giving users confidence that the machine can adapt to ongoing requirements without significant downtime.

Cost Benefits of Spare Parts Access

When evaluating outdoor tools, many users focus on the purchase price alone. However, ongoing costs play a major role in overall value. A brush cutter that offers accessible spare parts reduces long-term expenses because users replace only what is necessary. For the BG35H, this means the gear case or shaft can be serviced independently, ensuring the machine continues to deliver value year after year without forcing a complete replacement.

Building Confidence in Equipment Choice

For buyers considering a brush cutter for sale high quality, knowledge of how gear case shaft spare parts contribute to cutting performance is key. Instead of viewing the machine as a short-term solution, they can plan for maintenance and see it as a long-term investment. The BG35H demonstrates how attention to component quality and spare part availability directly impacts both immediate results and future usability, making the machine a practical choice for varied outdoor tasks.

English

English русский

русский Español

Español عربى

عربى