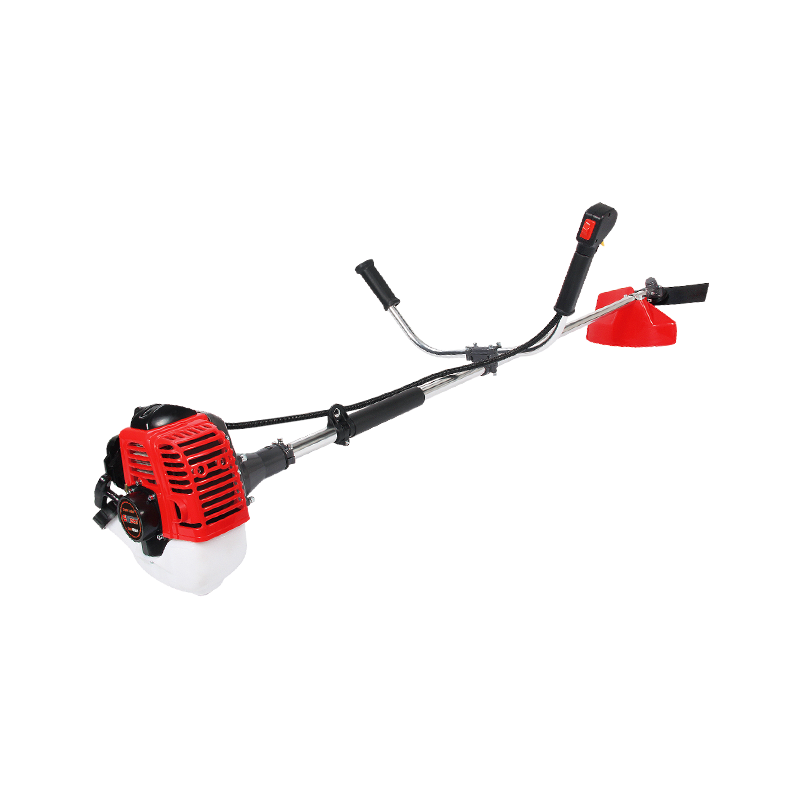

Across forestry, landscaping, and construction industries, users increasingly look for tools that deliver consistent performance over time. Among these, the gasoline chain saw manufacturer plays a crucial role in ensuring the durability, usability, and efficiency of professional cutting tools. Models like the Gasoline Chainsaw Single Starter reflect how modern design and production processes are evolving to meet current needs. Understanding what defines a dependable manufacturer today helps both professional users and equipment buyers make informed decisions when selecting machinery for long-term or high-intensity projects.

Manufacturing Standards and Technical Control

Behind every high-performing gasoline chain saw lies a combination of precise engineering and strict manufacturing standards. Manufacturers that specialize in gasoline-powered tools typically maintain a complete production process—from raw material selection to assembly and quality inspection. Factors such as machining accuracy, engine calibration, and material treatment directly affect the saw’s cutting stability and service life.

Modern facilities often use automated production lines and digital control systems to ensure consistency. For example, engine components must meet specific tolerance levels to prevent vibration and energy loss during operation. Likewise, the alignment of the guide bar and chain drive influences cutting precision and safety. When these technical details are handled properly at the manufacturing level, users benefit from a tool that performs smoothly and requires less adjustment during use.

The Role of Design Innovation

The Gasoline Chainsaw Single Starter illustrates how thoughtful design can improve user experience without adding unnecessary complexity. A single-starter system allows for faster ignition, reducing the time and physical effort required to start the engine.

Beyond starting mechanisms, design innovation extends to the ergonomics of the handle, the weight balance of the saw body, and vibration-dampening structures. These improvements collectively reduce operator fatigue, which is critical for users who rely on the machine for extended working hours. Manufacturers that continuously update their designs in response to real-world usage feedback demonstrate a deeper understanding of end-user challenges.

Materials and Component Quality

Another defining factor of a strong gasoline chain saw manufacturer is the selection of materials. The chain, bar, and engine casing must withstand long periods of stress and exposure to heat, oil, and moisture. High-carbon steel, wear-resistant alloys, and corrosion-protected surfaces are commonly used in well-built models.

Attention to detail in material processing determines how long the saw can maintain sharpness and power without frequent maintenance. Even smaller parts, such as the fuel filter, carburetor diaphragm, and spark plug components, must be manufactured or sourced according to precise standards. A chain saw that uses carefully tested materials not only ensures better performance but also reduces total operating costs over time.

Quality Inspection and Testing Procedures

To maintain consistency, professional manufacturers integrate strict testing procedures into their production lines. Each unit may undergo multiple functional checks before shipping, including engine ignition tests, vibration measurements, and chain movement assessments. Such steps are not only about verifying power output but also about ensuring the overall safety and smooth operation of the saw.

Testing also covers environmental adaptability. A chain saw must perform under a range of temperatures, altitudes, and humidity levels. Manufacturers conduct endurance testing to simulate real-world conditions, allowing them to refine the design before mass production. These continuous testing efforts reflect a manufacturer’s commitment to stable performance and product safety.

Maintenance Accessibility and User Support

For users handling large projects or operating fleets of equipment, maintenance accessibility is an important consideration. A well-structured gasoline chain saw should allow for easy access to critical parts such as the air filter, spark plug, and chain tensioner. Manufacturers that design their products with simple disassembly options enable users to perform regular maintenance efficiently.

In addition, providing clear documentation and technical support adds value to the equipment. Some manufacturers offer detailed user manuals, maintenance guides, and spare parts references to assist operators in troubleshooting or routine servicing. This kind of after-sales support ensures the saw continues to perform effectively throughout its lifespan, reducing downtime in professional operations.

English

English русский

русский Español

Español عربى

عربى